Gateway Technical College using 3D printer to make masks for first responders, others

RACINE -- With first responders scrambling for more personal protective equipment (PPE), Gateway Technical College in Racine is stepping in to fill the void with 3D printers.

With every spin of the spool, what began as a concept to help address the nationwide PPE shortage is now yielding results.

John Zehren leads the "Fab Lab" at Gateway which is now producing PPE for local first responders, hospitals and more.

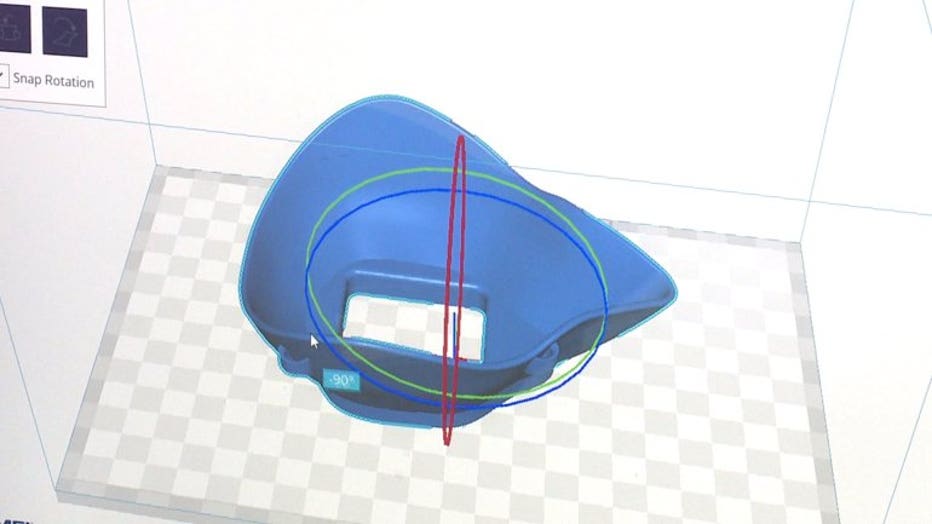

"They're drawn in CAD software, then they are sliced, and that resulting G-code gets put into the printer, and then it makes the model," said Zehren. "I've had emails from people who aren't even Gateway students who have printers, who want to help. Everyone who sees wants to participate, wants to help any way they can."

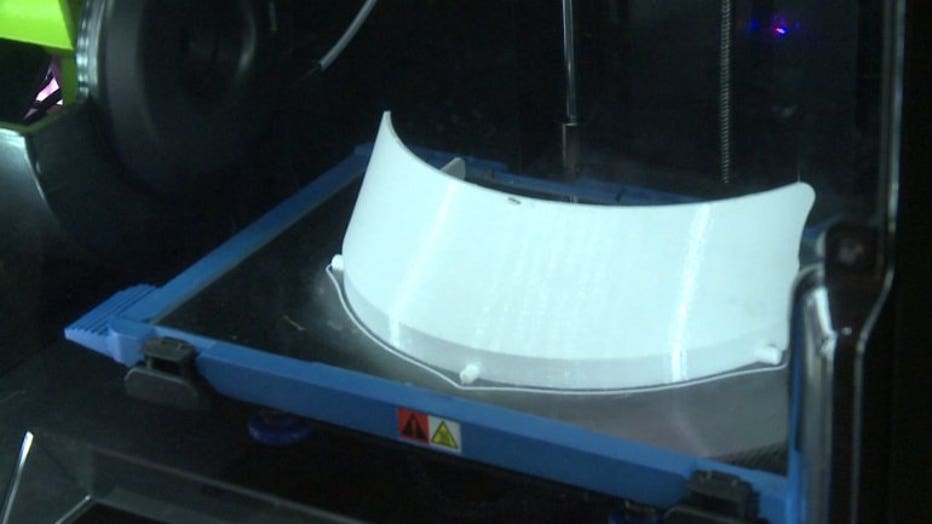

Initially starting with masks, the lab has transitioned to a few other forms of PPE like face shields -- assembled with a three-hole punch -- and straps to be used on the back of the head as a way of cutting down on pain caused by wearing a shield or mask.

John Zehren

The base of the face shields take anywhere from three to five hours to print before attaching the shield itself. The lab is also sharing its files for other printers to use. Anyone who is interested -- or in need of PPE -- can email Zehren at zehrenj@gtc.edu.